Thermal Engineering (313310) Practical No:14 Assembling and dismantling of single cylinder I.C Engine Answer

After performing this practical students will learn about various engine components such as the cylinder, piston, crankshaft, camshaft, valves, and fuel injectors. This knowledge is crucial for understanding how each part functions and interacts with others. Students learn how to utilize torque wrenches, micrometers, and other tools and instruments that are necessary when working on engines. Practical acquaintance with engines is required for many mechanical engineering positions. This hands-on training makes students more job-ready, providing them an advantage in the employment market. Learning how to assemble and dismantle an engine helps students acquire diagnostic abilities. They know how to detect and troubleshoot typical problems such as engine knocking, misfiring, and oil leaks.

Thermal Engineering (313310) Practical No:14 Procedure

1. Select the available I.C. engine model for dismantling.

2. Select the proper tools and equipment.

3. Apply recommended tools to remove engine accessories and components of an

I.C. engine.

4. Identify the various subassemblies and accessories of the Engine

5. Understand the functions of different parts.

6. Examine all the components carefully

7. Observe their physical and functional conditions.

8. Locate different areas that need maintenance/replacement.

Observation and calculations

Practical-related questions

1. List the basic tools for dismantling and assembling a single-cylinder IC engine. State its purpose

Answer:

2. State the precautions to be taken before starting the dismantling process of an IC engine.

Answer:

• Avoid improper handling of an I.C. Engine.

• Use special and recommended tools for the assembly and dismantling of an I.C.

Engine.

• Use a clean workbench for the assembly and dismantling of an I.C. Engine.

• Care must be taken while removing the components.

3. Write the recommended sequence for assembling a single-cylinder IC engine.

Answer:

4. Draw a neat labeled sketch of a piston

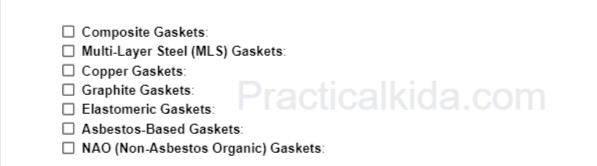

5. List the name of the gasket material used in the cylinder head.

Answer:

We completed Thermal Engineering (313310) Practical No:14 and done Assembling and dismantling of single cylinder I.C Engine.